Gadgil and his team had to design a stove that was not only more efficient but that also would work for the refugees in Darfur. Additionally, it needed to be cheap and easy to mass produce. In order to do this, Gadgil’s team used what’s called a user-centered design approach. This means that the needs of the people who would be using the stove were carefully considered every step of the way.

The design of the stove had to meet several requirements:

- It had to cook food more efficiently than traditional cooking methods.

- It had to work with the cooking style of refugees in Darfur—it had to fit their pots, burn the fuel they burned, cook the food they cook.

- The stove had to be cheap to make and easy to manufacture or assemble in Darfur.

The team began by trying to understand exactly how residents cooked their food. What types of pots did they use? What foods did they cook? How often did they cook? How much wood did they use? Did they cook indoors or outdoors? All of this information influenced the stove’s design. For example, they wanted to make sure that the stoves were big enough to fit the common pot sizes, but if the stoves were too big they would require more wood.

Gadgil’s team was able to get a rudimentary understanding of cooking techniques by talking to aid workers, but it soon became clear that they needed to go to Darfur to gather more information. In 2005, Gadgil led a team to Darfur. They brought several examples of stoves to test in cooking demonstrations in the camps. For each test, teams of local women simultaneously cooked the same amount of food on different stoves. This gave the researchers a side-by-side comparison of how much wood each stove used in order to cook the same amount of food. The women also gave the researchers feedback about the performance of each stove.

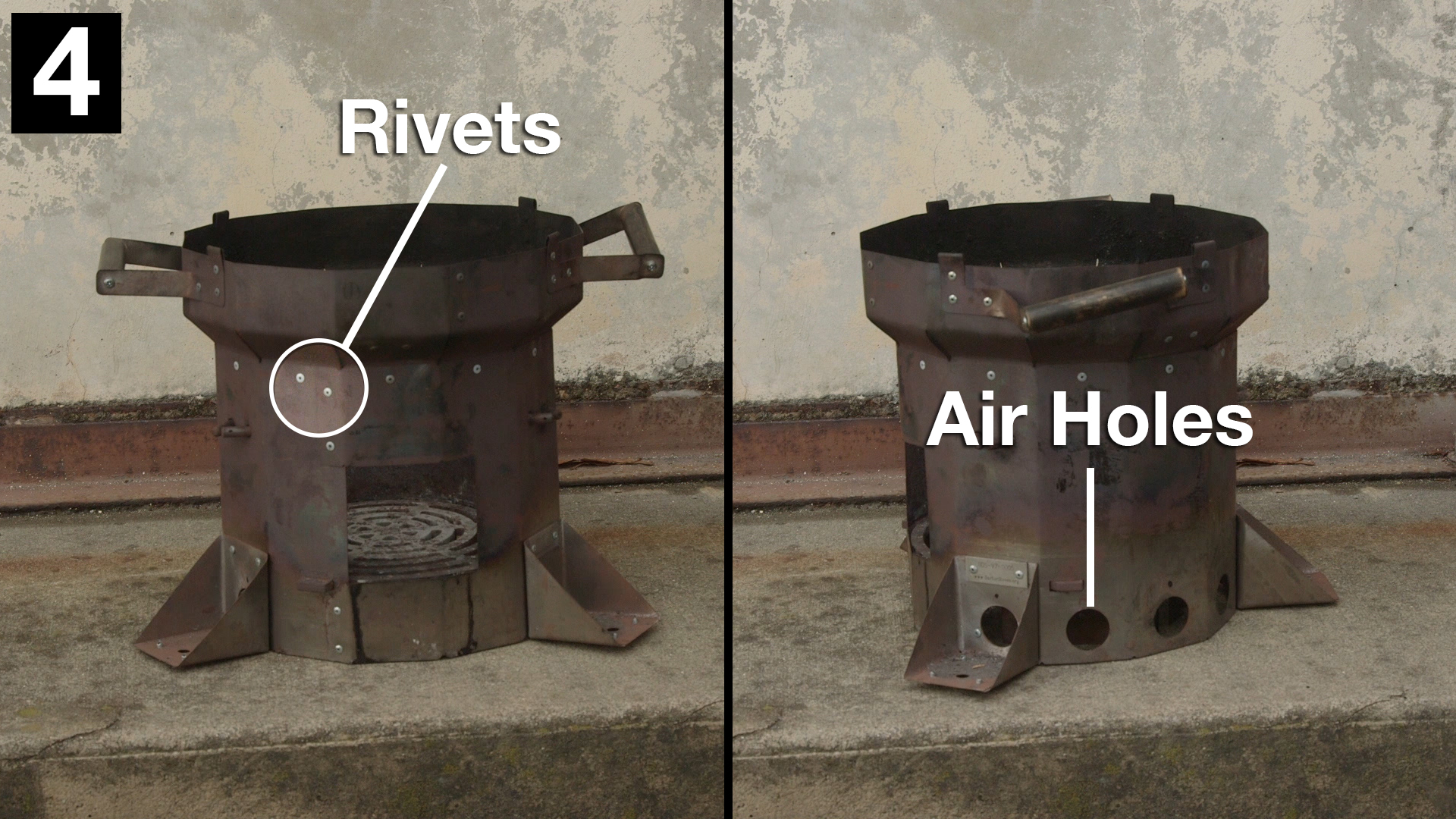

After conducting these tests and talking to residents of the camps, Gadgil’s team decided that one of the stoves they brought was a winner, but it required a few alterations. The team had learned that one common dish in Darfur requires vigorous stirring, so they needed to make sure the final stove design could stand up to that. The team also observed that the women often cook outdoors. Cool breezes can reduce the efficiency of the fire, so the new stove needed to work well in gusty wind conditions.

Armed with this information, Gadgil’s team returned to the lab to design a better stove. They made alterations and tested the redesigned stove, repeating this process until they were satisfied. They also were able to design a stove that can be assembled in Darfur, creating jobs and generating income for the region.

What makes this stove more efficient than a three-stone fire?

In order to understand what makes a more efficient stove, we first need to take an in-depth look at a three-stone fire. A three-stone fire is an inefficient way to cook food for two main reasons: 1) incomplete combustion of wood, and 2) poor heat transfer from the fire to the pot.

Incomplete Combustion of Wood

If you’ve ever tended a campfire, you have some idea of how hard it is to get a fire to burn evenly and steadily. That’s because you need three things, all in the proper combination, in order to get a fire to burn: fuel (such as wood), oxygen and heat. These requirements are referred to as the “combustion triangle.” Campfires, especially those on the ground, don’t receive enough oxygen for the wood to burn completely. Similarly, windy conditions can lower the heat the fire needs in order to burn, weakening the fire and resulting in incomplete combustion. As a result in order to cook food that requires heat for a long period of time, you have to constantly add wood to the fire.

What happens when wood burns? Learn about the chemistry of combustion. Having trouble viewing the video? Stream or download it here.

Poor Heat Transfer from Fire to Pot

With a three-stone fire, a lot of heat generated by the fire is lost to the environment. Only a small portion of the heat is directed to the pot. As a result you need a larger fire to more evenly heat the pot and food, and a larger fire burns more wood.

So how is the Berkeley-Darfur Stove more efficient than a three-stone fire? Basically, the stove reduces cook time and fire size by shielding the fire from the wind and directing heat from the fire to the pot. This allows the stove to cook food more quickly while also using less wood.